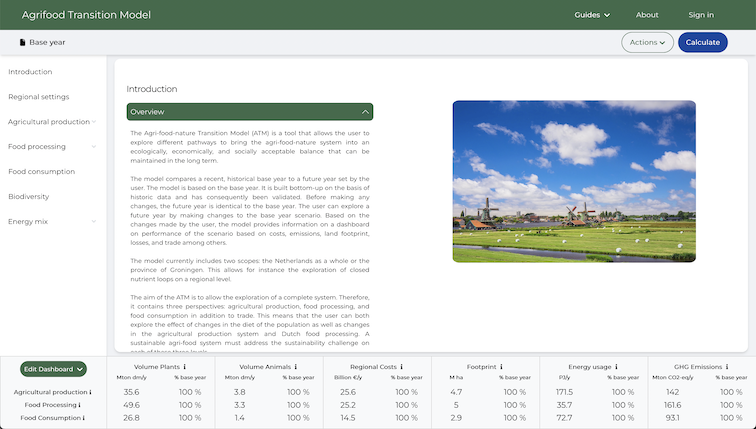

Agri-food-nature Transition Model (ATM)

The Agri-food-nature Transition Model (ATM) is a simulation tool for exploring a future Dutch agricultural and food system. It allows the user to make changes to both volumes of production and consumption as well as the manner of production. The model in turn provides feedback for the user for instance regarding nutrient losses, circularity, emissions, land footprint and impact on biodiversity. The ATM was developed in collaboration with a wide consortium consisting of stakeholders in the field of agriculture and food processing, as well as the Institute for Sustainable Process Technology (ISPT), NGOs, and Wageningen University and Research (WUR).

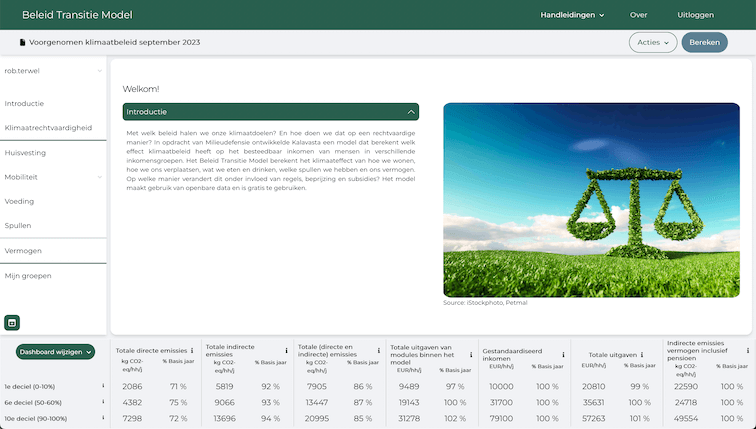

Beleid Transitie Model (BTM)

The Beleid Transitie Model (BTM, Dutch only) is a simulation tool for exploring the effects of Dutch policy on household consumption, expenses and emissions for different income groups. It allows the user to explore the effect existing policies or introduce new ones, with a focus on the consumer side. The model calculates how these taxes, norms and subsidies affect household spending and emissions. In addition it is possible to simulate an individual user-specified household. The BTM was developed for the NGO Milieudefensie (Friends of the Earth Netherlands) and was used to evaluate the Dutch climate policy plans in September 2023.

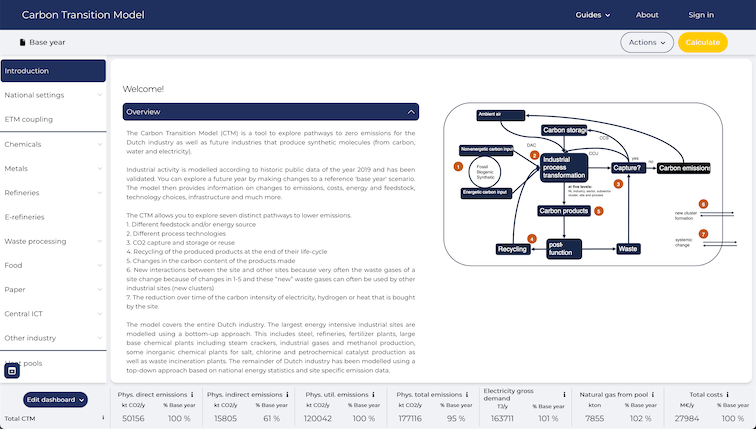

Carbon Transition Model (CTM)

The Carbon Transition Model (CTM) is simulation tool for exploring routes to a future climate-neutral Dutch heavy industry. The model allows the user to change both the production volumes as well as feedstocks and production technologies and provides in turn feedback on for instance emissions (direct, indirect and downstream), costs and demand of feedstocks. The CTM was developed in collaboration with many industrial companies, with help from knowledge institutes and the Institute for Sustainable Process Technology (ISPT).